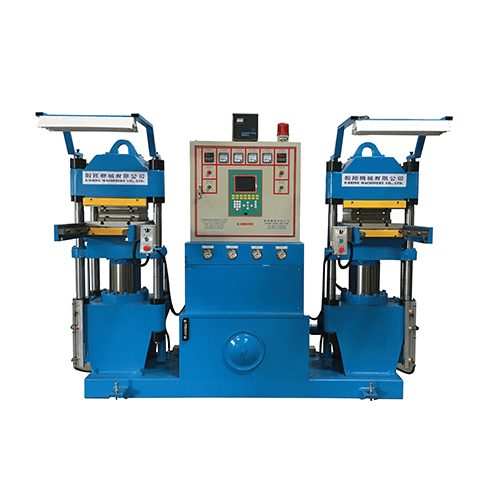

Classification : High-Speed Hot Press Molding Machine

Country:

Phone: 886-37-585326

Fax: 886-37-583363

Contact Person: Jack Lin

1. In/Out molds:

Designed with special isolating devices to prevent wearing of the heat plate and the in/out-mold plate.

2. Front ejector:

Using double-layer oil-less bearings, protected with a dust seal.

3. Monitoring design:

Overall monitoring on machine actions, pressure and flow rate, and warning messages and records.

4. Hydraulic circuit design:

Fully proportional hydraulic system, pressure and speeds can be easily adjusted.

5. Electrical control system:

5-1. Precise temperature controlled is using PID calculations, temperature can be adjusted by the man-machine interface.

5-2. The module saving function includes temperature, pressure/ flow rate, time and function settings.

5-3. Heating system: using SSR solid relay with fast heat-up without exceeding the limit.

5-4. Mold calibration: slow mode calibration function is provided. To calibrate the mold, simply press up/down key to complete the mold position setting.

Designed with special isolating devices to prevent wearing of the heat plate and the in/out-mold plate.

2. Front ejector:

Using double-layer oil-less bearings, protected with a dust seal.

3. Monitoring design:

Overall monitoring on machine actions, pressure and flow rate, and warning messages and records.

4. Hydraulic circuit design:

Fully proportional hydraulic system, pressure and speeds can be easily adjusted.

5. Electrical control system:

5-1. Precise temperature controlled is using PID calculations, temperature can be adjusted by the man-machine interface.

5-2. The module saving function includes temperature, pressure/ flow rate, time and function settings.

5-3. Heating system: using SSR solid relay with fast heat-up without exceeding the limit.

5-4. Mold calibration: slow mode calibration function is provided. To calibrate the mold, simply press up/down key to complete the mold position setting.

| TyPE | 100 TON | 150 TON | 200 TON | 250 TON | 300 TON | 500 TON |

| Stroke (mm) | 250 | 250 | 250 | 250 | 250 | 300 |

| Upper heater Plate (mm) | 400*400 | 440*440 | 510*510 | 600*600 | 600*600 | 850*850 |

| Lower heater Plater (mm) | 445*450 | 500*500 | 540*560 | 650*600 | 650*650 | 850*850 |

| Mold in-out plate (mm) | 445*500 | 550*560 | 540*570 | 650*650 | 650*680 | 855*880 |

| Piston diameter (mm) | 250 | 300 | 350 | 400 | 450 | 560 |

| Electrical heater (KW) | 22 | 34 | 34 | 34 | ||

| Motor (HP) | 15HP | 15HP | 15HP | 15HP | 10HP*2 | 10HP*2 |

| -single | -single | -single | -single | -twin | -twin | |

| Total power (KW) | 40 | 48 | 52 | 52 | ||

| Size | ||||||

| Mold opening Method | 0RT: up/down 3RT: middle mold | |||||

| 1RT: in/out 4RT:Top mol | ||||||

| 2RT: front ejector | ||||||