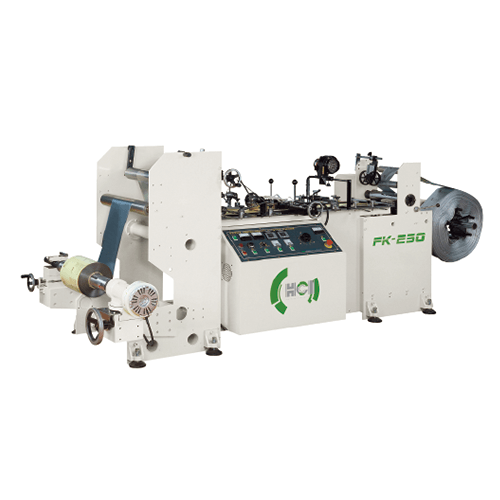

Classification : Slitting Machine Slitter Rewinder

Country: Taiwan

Phone: 886-4-2359-0632

Fax: 886-4-2359-0710

Contact Person: Mr. Alan Ho

Product ID: FSL-V

FSL-V Slitting Machine is specially designed for the plastic films which are of variable thicknesses, low tension demand or tension strictness. It is also suit for slitting a wide variety of materials such as, cellophane, PET, OPP, CPP, PE, PVC, paper roll, and printed films.

● Equipped with shaftless & pneumatic-chuck unwind stand.

● Auto unwind tension control.

● Two servomotor drive system providing the most accurate winding control.

● Adopted duo slitting system on the V series slitting machine.

● Rewinding Individual lay-on roller 4 sets.

● Laser core positioning system. (optional)

● Products discharge device.

● Inner pressure type differential rewinding shafts.

● Micro computer controller

-LCD colorful touch screen and simple figure display for setting.

-Dialogue parameter setting environment for fast start.

-Rewind tension auto increase function.

-Unwind auto stop and material brake stop function.

-Parameters memory function: included material thickness, initial diameter, tension and so on.

● Auto unwind tension control.

● Two servomotor drive system providing the most accurate winding control.

● Adopted duo slitting system on the V series slitting machine.

● Rewinding Individual lay-on roller 4 sets.

● Laser core positioning system. (optional)

● Products discharge device.

● Inner pressure type differential rewinding shafts.

● Micro computer controller

-LCD colorful touch screen and simple figure display for setting.

-Dialogue parameter setting environment for fast start.

-Rewind tension auto increase function.

-Unwind auto stop and material brake stop function.

-Parameters memory function: included material thickness, initial diameter, tension and so on.

| Specifications | FSL-V1300 Slitting Machine |

| Mechanical Speed (m/min) | 300 |

| Unwind Stand | Shaftless with Pneumatic Chuck & Floating Type |

| Core Inner Diameter (mm) | 76 / 3" or (152 / 6" Optional) |

| Web Width (mm) | 320 - 1,300 |

| Maximum Unwind Diameter (mm) | 1,000 |

| Unwind Tension Control | Magnetic Powder Brake With Load Cell Sensor |

| Web Guiding System | Printing Line / Edge |

| Guider Movement (mm) | +/- 50 |

| Slitting Techniques | Razor In Groove Roller / Shear Knives |

| Trim Removal | Vacuum Type Trim Disposal |

| Minimum Rewind Web Width (mm) | 50 |

| Maximum Rewind Diameter (mm) | 600 |

| Rewind Tension Control | HCI Differential Winding Technology (Inner pressure type) |

Product ID: FSL-V Deluxe

FSL-V Slitting Machine is specially designed for the plastic films which are of variable thicknesses, low tension demand or tension strictness. It is also suit for slitting a wide variety of materials such as, cellophane, PET, OPP, CPP, PE, PVC, paper roll, and printed films.