Rotary Die Head & Rotator

Categories : Mold Parts

+For LDPE / LLDPE blown film machine. +To stablely control the product thickness, enhance cooling effect and improve product quality.

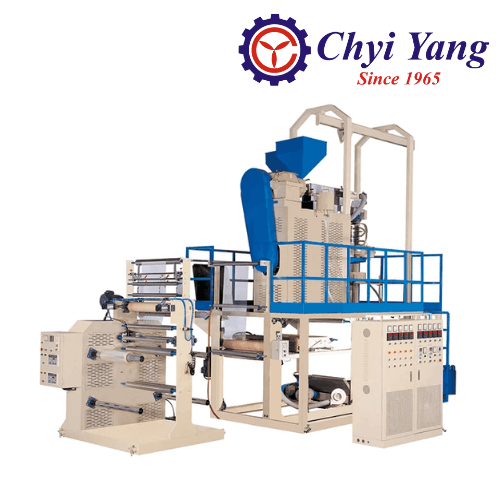

TWO STRIPE COLOR BLOWN FILM MACHINE

Categories : Blown Film Extruders

TCP-H is designed by two independent motors, gear boxes and extruders to produce films with two colors stripes TCP-SE is designed by one motor, one gear boxes & two extruders to produce film with two colors stripes TCP-H makes width of two colors can be adjustable TCP-SE is for saving cost of machine & less capacity The precise die design makes the colors vivid, clear & won’t be mixed together Purchasing a 2-layer co-extrusion die can produce 2-layer film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

LDPE Zipper Blown Film Machine With Rotogravure In Line Printing Machine (AEZ-45/55+ARP800i)

Categories : Blown Film Extruders

LDPE ZIPPER BLOWN FILM MACHINE with ROTOGRAVURE IN LINE PRINTING MACHINE(AEZ-45/55+ARP800i)

Pallet Net

Categories : Industrial Knitting Machines

Raschel Knitting Machines,, Blown Film Machines, Pallet Net

HDPE Blown Film Machine

Categories : Blown Film Extruders

HDPE Blown Film Machine In the past 30 years, we have been keeping receiving very good reputation from our worldwide customers on our quality products and satisfactory services.

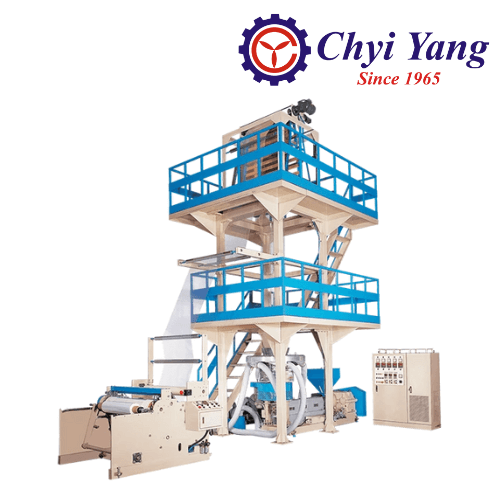

WATER COOLING DOWNSTREAM 2-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine, CHYI YANG is Multilayer Co-Extrusion Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

SUPER HIGH SPEED HDPE/LDPE/LLDPE BLOWN FILM MACHINE

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Easy installation & operation Adjusting thickness easily by screws of die, high capacity & less plastic waste Automatic flying cutter & manual change reels winder, flying cutter to match the machine speed, won’t be re-winded on the nip roller Main Motor is driven by inverter for better performance & less electricity Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Blown Film Take-Up Unit

Categories : Blown Film Extruder Parts

HSIN LONG Setting in the highest part of Plastic Film Blowing Machine, the most classic type of Take-Up Unit is suit for most Blown Film Machines. Different with the Oscillating Haul-Off, the volume is smaller and not take spaces.

HIGH SPEED TWIN DIE BLOWN FILM MACHINE

Categories : Blown Film Extruders

TDH series is one extruder provides two dies to get bigger capacity & less space. TDH-S series is standard machine. TDH-F series is forced feeding type for more output & faster speed. Purchasing extra LDPE die can produce LDPE film.

Single Layer Die Head for HDPE or LDPE or PP

Categories : Extrusion Dies / Dies Heads

+Suitable for HDPE, LDPE & LLDPE Blown Film Machine. +Low pressure and spiral design provide high stability & high production. +All steel is made of Japanese SCM-440 through strict & precise processing procedure with reliable quality.

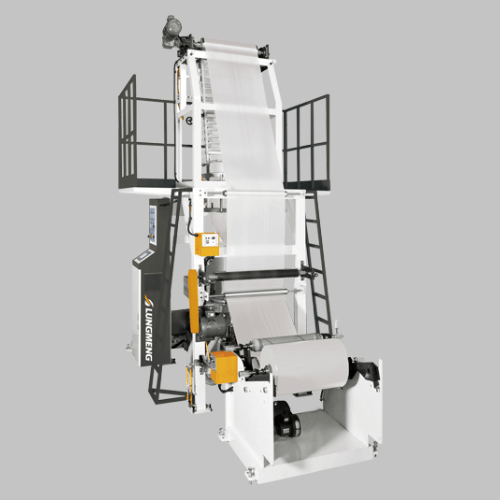

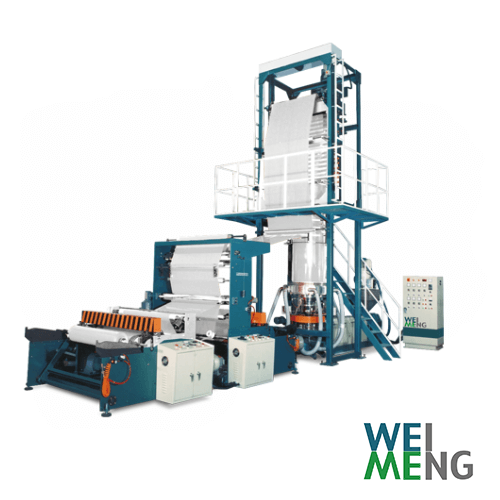

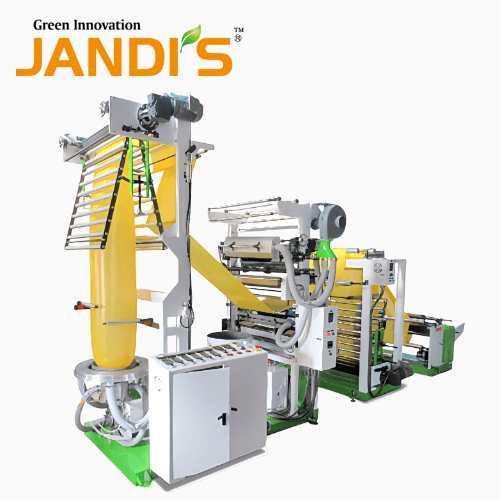

LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Double lip air ring & better cooling system to support the high speed capacity Can produce LDPE, LLDPE and shrinkable film Slitting device and double winder (up-and-down & back-to-back type) is offered to produce single layer film rolls. Optional Rotating die device is making uniform thickness film for printing & laminating purpose Optional Co-speed controller matches same speed for take-up unit and winder to avoid film to be stretched Purchasing HDPE die can produce HDPE film Fully automatic winder makes machine automatically & save time of operators We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Two Layer AB blown film machine

Categories : Co-Extrusion Blown Film Machines

For two color film production Extruder dia. 45mm, 55mm or 65mm

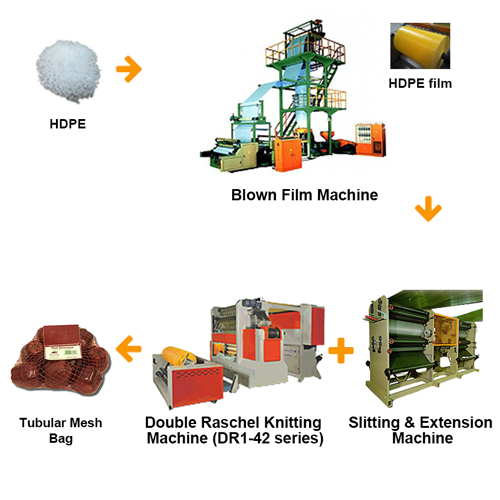

Tubular Mesh Bag

Categories : Industrial Knitting Machines

Tubular Mesh Bag, Blown Film Machine, Raschel Knitting Machine

LDPE High Speed Zipper Blown Film Machine(AEZ-45/55)

Categories : Blown Film Extruders

LDPE HIGH SPEED ZIPPER BLOWN FILM MACHINE(AEZ-45/55)

High Speed Stretch & Cling Blown Film Machine

Categories : Blown Film Extruders

AH75SC(PIB) MONO-LAYER HDPE/LDPE/MLDPE/PP Designed to produce Stretch and Cling films with high transparency and superior strength Double station back to back winder with servo driven micro-tension control system High quality mixing in screw and barrel delivers excellent homogeneity and high output

Heavy-Duty Bag Blown Film Production Line

Categories : Blown Film Extruders

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.

PVA Water Soluble Blown Film Machine - GF-AV35.45

Categories : Blown Film Extruders

PVA base water soluble, compostable and biodegradable eco-friendly material

ZIPPER BAG BLOWN FILM MACHINE

Categories : Blown Film Extruders

Designed to produce single line & double lines zipper bags, double zipper bags are upto the bags size & die. Different range film length should match different die & cooling ring Color injection extruder is an option.

MINI TYPE BLOWN FILM MACHINE

Categories : Blown Film Extruders

Designed for T-Shirt bag and flat bag production Small occupancy of space Simple, flexible and economic operation High output and saving energy Also can work with LDPE resin if changing air ring Film thickness HDPE 0.008~0.06 mm

Corona Treater -T Series / For Blown Film Line

Categories : Blown Film Extruders

Corona treater is a surface modification technique for adhesion improving treatment and increase dyne level. It uses a low temperature corona discharge plasma to impart changes in the properties of a surface. Materials such as plastics, cloth, or paper may be passed through the corona plasma curtain in order to change the surface energy of the material. All materials have an inherent surface energy. Surface treatment systems are available for virtually any surface format including dimensional objects, sheets and roll goods that are handled in a web format. Corona treatment is a widely used surface treatment method in the plastic film, extrusion, and converting industries. It is also known as plastic surface treater, surface corona treater, air plasma, corona discharge treatment, corona treating, Corona-discharge Plastic Surface Treatment Equipment, corona treatment machine, corona treatment device and corona treatment. Application Extrusion: .Blown film extrusion / Blown film machine / ABA co-extrusion / Inflation machine .Cast film / sheet extrusion / Extrusion coating / coating lamination / Extrusion lamination / tandem extrusion lamination Printing: .Inline Printing press / printing machine / Rotogravure printing machines / woven bag printing / label printing / Solvent printing / water base printing / Flexo printing / T shirt bag printing Converting .Slitting rewinder / coating / wet lamination / dry lamination / hot lamination / solventless lamination / Rotogravure coating machines /gluing / bonding / tandem lamination Model CH-800S / CH-1000S / CH-1200S / CH-1500S / CH-2000S / CH-3000S / CH-5000S CH-800T / CH-1000T / CH-1200T / CH-1500T / CH-2000T / CH-2KT CH-3000T / CH-5000T / CH-8000T CH-3KT / CH-5KT / CH-8KT / CH-10KT / CH-12KT / CH-15KT / CH-20KT CH-3KD / CH-5KD / CH-8KD / CH-10KD / CH-12KD / CH-15KD / CH-20KD Substrate material HDPE, LDPE, LLDPE, MLLDPE, PET, PVC, PP, OPP, CPP, BOPP, PI, PS, PC, EVA, Nylon, PTFE, PU, TPO, TPE, TPO, Bio degradable , Biodegradable, Bio-degradable, Stretch film PE woven, PP woven Hollow profile sheet, corrugated sheet, Cartonplast, Polyflute, Coroplast , FlutePlast, IntePro, Proplex, Correx, Twinplast, Corriflute, Corflute Metalized film, FPC, Foil, copper foil, electrodepositedcopperfoil, CCL Non woven, Melt blown, Fabric, textile