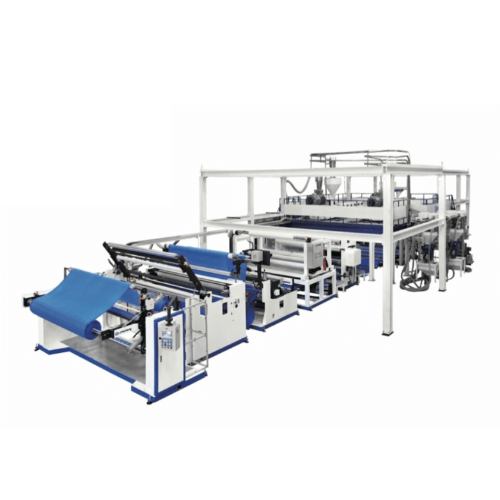

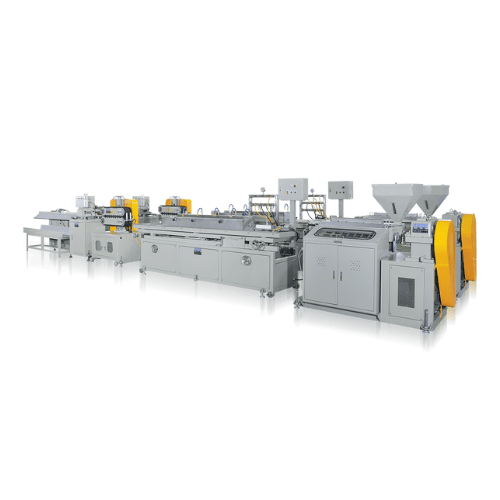

3-Layer Air Bubble Film Extrusion Line

Categories : Air Bubble Film / Sheet Extruders

The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive.Agricultural sector (green house) with anti-UV additive.Covering of swimming pool with anti-UV additive.Typical packaging with anti-shock, anti-abrasion and anti-crushing functions.Laminated with paper, PE woven and aluminum foil for making envelope.

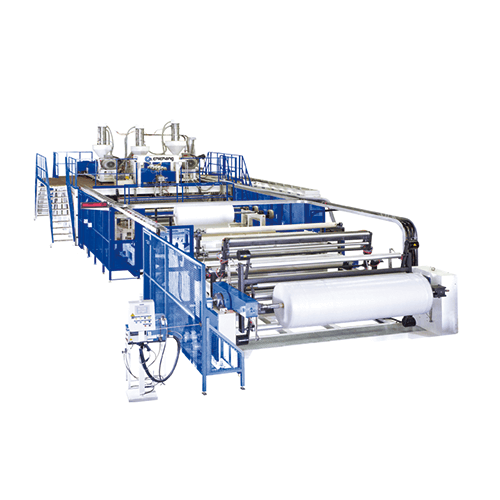

2.5M wide, 3-layer Air Bubble Film Extrusion Line (With 2 Unwinders)

Categories : Air Bubble Film / Sheet Extruders

Various models to meet with your needs. Sheet width from 1,200MM to 2,500MM, from 2 layers to 10 layers. Tailored-made machine available.

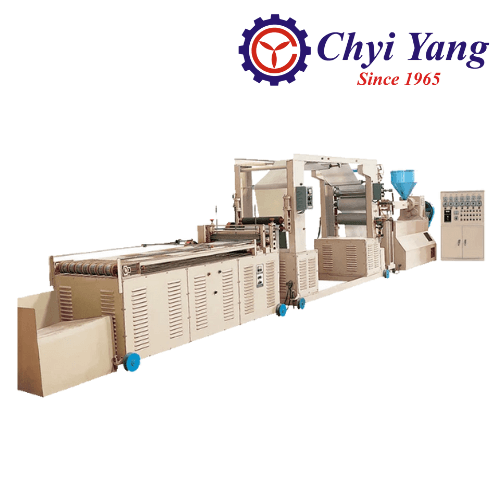

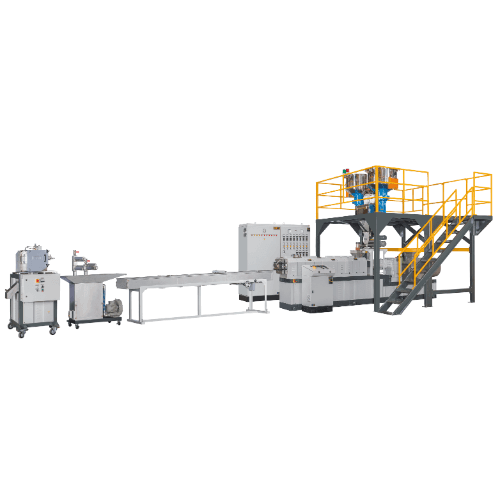

PE Foam & PE/PP Sheet Extrusion Line

Categories : Foam Extruders

T-Die Extruder machine is equipped with cutter or winder to produce PP/PE sheets PP sheet is available in file cover, stationary etc. Film thickness 0.5~2.5 mm For different machines’ structure, can produce PE, PP sheet & PE foam sheet. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

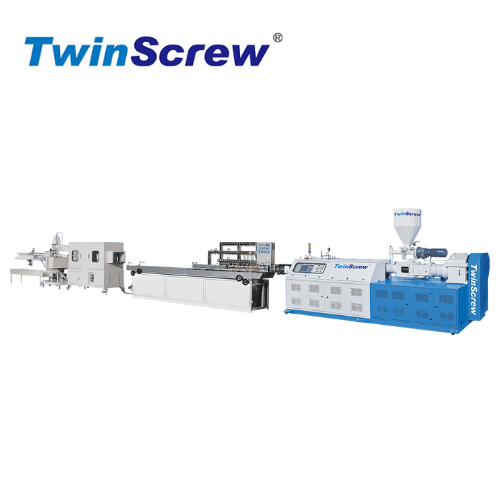

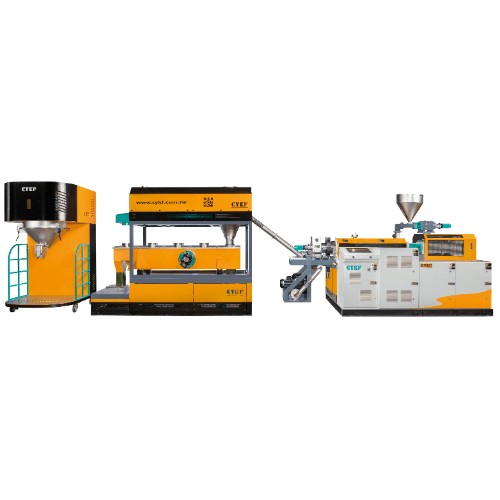

Medical Grade PVC Pelletizing Extrusion Line | CK-DT

Categories : Twin Screw Extruders

CYKF has good reputation in PVC extrusion. Our CK-DT Counter-rotating Twin Screw Extruder is especially designed for PVC production; the available screw diameter is between 55 to 130mm. Thanks to our technical team put long term effort on PVC extrusion technology which makes CYKF’s PVC extruder is competitive compared to other competitors. The high-efficient and durable PVC pelletizing machine can produce rigid PVC, soft PVC, medical grade PVC, UPVC, CPVC, and additives of foam or wood powders. It has outstanding performances that has earned highly praises from global customers.

WPC PROFILE EXTRUSION LINE - PE/PP/PS/TPE/PVC

Categories : Extrusion Lines For Pipes and Profiles

The WPC profile extrusion line is a set of machines used in the production of WPC boards. Differences between WPC profile extrusion and general profile extrusion WPC profile extrusion machine is different from general profile extrusion machine, It has to maximize mixing while minimizing damage to the biomass furnish because the WPC material involves two different types of materials: wood and plastic. It is more accurate processing temperature, melt flow index, etc. are required. The same is that general profile extrusion is a process by which various plastic materials are used to develop quality plastic products that have a feature of continuous (ex: plastic board) but do not include sheet or film products. How does WPC profile extrusion line work? The process of WPC profile extrusion begins with the mixing of wood powder and plastic in the mixer. The ratio of wood powder to plastic varies depending on the desired strength and durability of the final product. Once the mixture is blended, it is fed into the conical twin-screw extruder. The extruder has two screws that rotate in opposite directions, pushing the mixture through a barrel and melting it. The molten mixture is then pushed through a die that determines the shape and size of the extruded profile. The extruded profile is then passed through the vacuum calibration table, which cools it and sets its shape. The haul-off machine pulls the profile through the calibration table, maintaining its shape and ensuring its dimensions are correct. The cutting machine cuts the profile to the desired length, and the stacker stacks the finished product. Advantages of WPC profile extrusion line Efficient and consistent production of high-quality WPC profile products. The extrusion process ensures that the final product has a uniform shape and size, with consistent mechanical properties. Highly automated, reducing the risk of human error and increasing efficiency. Cheng-Yu Plastic Machine is a professional WPC profile extrusion line manufacturer As demand for sustainable, eco-friendly products continues to grow, the wood-plastic composite (WPC) market is booming. We develop WPC profile extrusion lines for profile manufacturers who need a reliable, efficient, and high-quality production process. It is a versatile and flexible solution for profile manufacturers in various industries.

2.5M wide 10-layer Co-Extrusion Air Bubble Film Extrusion Line

Categories : Air Bubble Film / Sheet Extruders

Packaging of electronic material with anti-static additive

PVC Pelletizing Extrusion Line | CK-DT

Categories : Twin Screw Extruders

CYKF is well-known in PVC extrusion. Our CK-DT series Counter-rotating Twin Screw Extruder is especially designed for PVC. The available screw diameter is between 55 to 130mm. We never stop improving our PVC extrusion technology and we love sharing ideas with customers. Our in-depth understanding of PVC enables us to design better extrusion lines compared to other competitors. CYKF’s PVC extruder is high-efficient and durable, its outstanding performances has earned highly praises from global users.

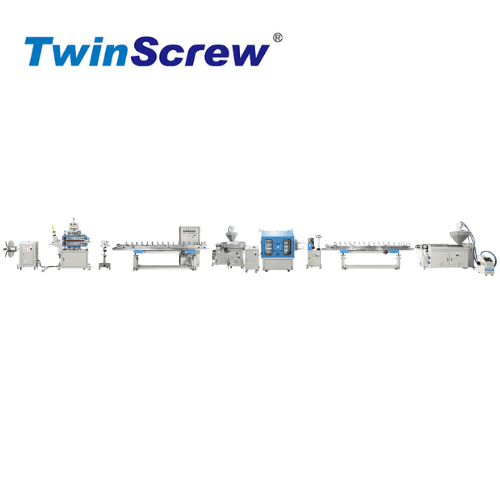

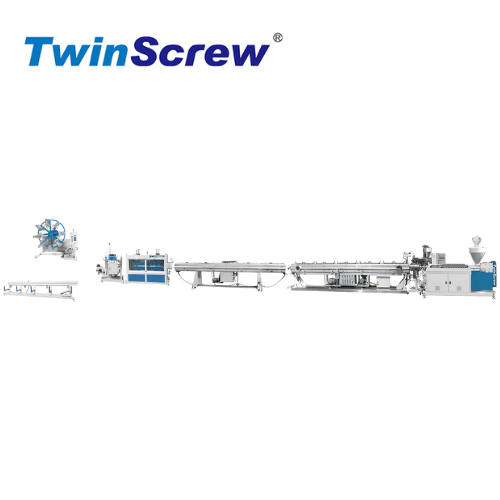

Co-rotating Twin Screw Strand Pelletizing Compounding Line | CK-HT

Categories : Twin Screw Extruders

CK-HT series Co-rotating Twin Screw Strand Pelletizing Compounding Extrusion Line is especially for composite materials that are suitable for strand pelletizing production method. It can be applied to a wide range of plastics. Possible materials: Various composite materials, e.g. PC, PE, PS, ABS, Nylon, LCP, PPS with additives of glass fiber, Wood powder, CaCO3.