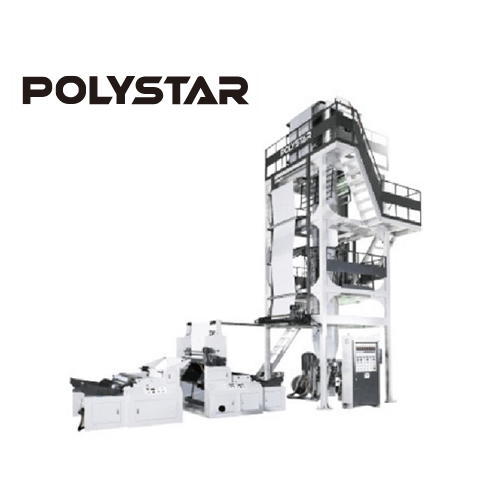

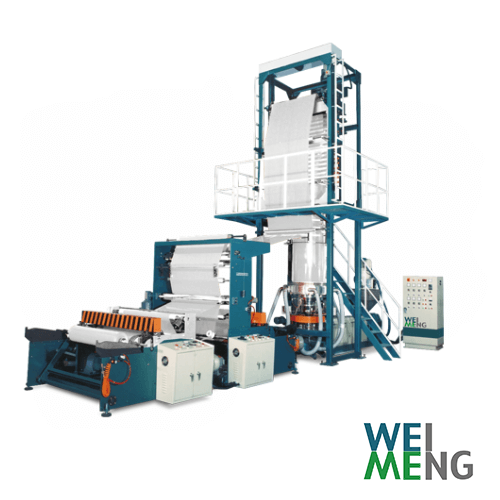

LDPE Zipper Blown Film Machine With Rotogravure In Line Printing Machine (AEZ-45/55+ARP800i)

Categories : Blown Film Extruders

LDPE ZIPPER BLOWN FILM MACHINE with ROTOGRAVURE IN LINE PRINTING MACHINE(AEZ-45/55+ARP800i)

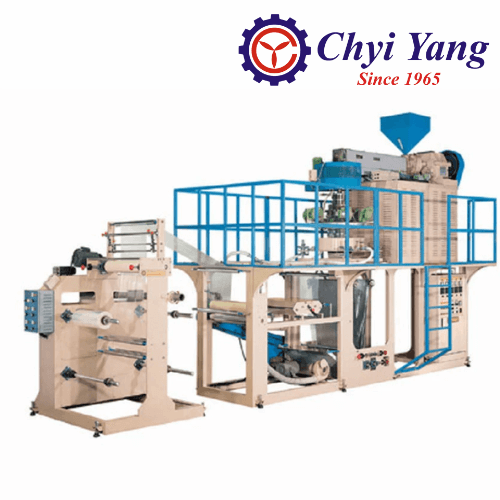

Blown Film Machine for Shrink Hood Film

Categories : Blown Film Extruders

Blown Film Machine for Shrink Hood Film

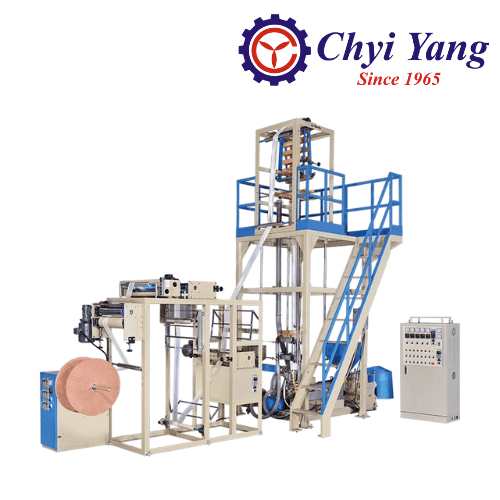

Two Layer AB blown film machine

Categories : Co-Extrusion Blown Film Machines

For two color film production Extruder dia. 45mm, 55mm or 65mm

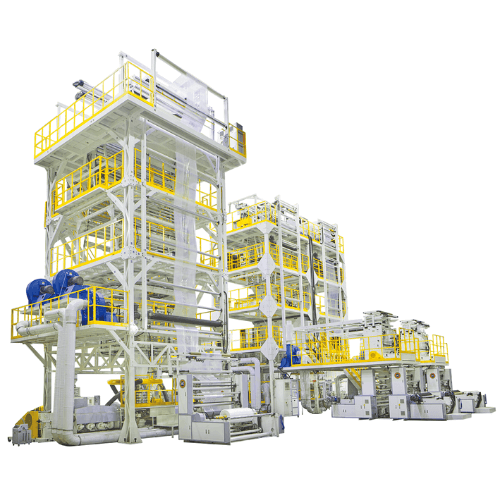

3 Layer Blown Film Machine for Shrink Hood Film

Categories : Blown Film Extruders

3 Layer Blown Film Machine for Shrink Hood Film

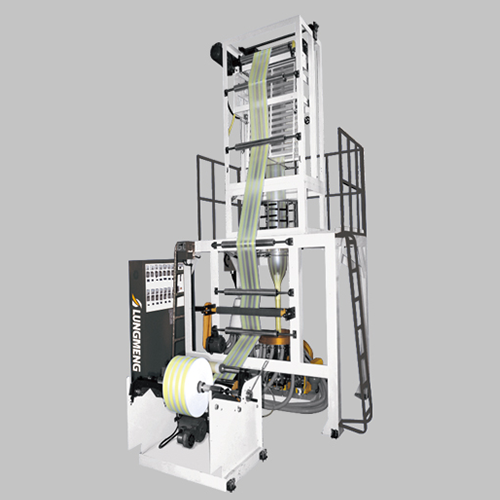

High Speed Two Color Blown Film Machine

Categories : Blown Film Extruders

Extruder Mono-Layer HDPE/LDPE/mLDPE/PPHigh Speed Two Color Blown Film Machine This machine can produce two color striped plastic film and the color can be changed according to customer's requirements Upgradable die and air ring for HDPE and LDPE multi-layer film production Widely used to produce agricultural film products such as agriculture covering cloth

2-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Available for agricultural film, coated film, stretch film, cling film, greenhouse film etc. Max film width up to 4.2 m (8.4 m in single-layer-opened film) Raw material HDPE, LDPE, LLDPE, EVA, MPE etc. Two sets of gearbox, motor & extruder for independent control For producing PE stretch/cling film, PIB liquid adhesion system can inject liquid adhesion into screw directly to save resin cost & adjust the stickiness ratio you need Purchasing PIB system can produce out-layer film non-sticky to prevent dust, in-layer film sticky to pack subjects Optional “Waste film recycling machine” lets this machine doesn’t have any waste plastic film, it can feed waste film directly into screw to save your cost We didn't show all our models, please don’t hesitate to contact us for bigger extruders.

Corona Treater -T Series / For Blown Film Line

Categories : Blown Film Extruders

Corona treater is a surface modification technique for adhesion improving treatment and increase dyne level. It uses a low temperature corona discharge plasma to impart changes in the properties of a surface. Materials such as plastics, cloth, or paper may be passed through the corona plasma curtain in order to change the surface energy of the material. All materials have an inherent surface energy. Surface treatment systems are available for virtually any surface format including dimensional objects, sheets and roll goods that are handled in a web format. Corona treatment is a widely used surface treatment method in the plastic film, extrusion, and converting industries. It is also known as plastic surface treater, surface corona treater, air plasma, corona discharge treatment, corona treating, Corona-discharge Plastic Surface Treatment Equipment, corona treatment machine, corona treatment device and corona treatment. Application Extrusion: .Blown film extrusion / Blown film machine / ABA co-extrusion / Inflation machine .Cast film / sheet extrusion / Extrusion coating / coating lamination / Extrusion lamination / tandem extrusion lamination Printing: .Inline Printing press / printing machine / Rotogravure printing machines / woven bag printing / label printing / Solvent printing / water base printing / Flexo printing / T shirt bag printing Converting .Slitting rewinder / coating / wet lamination / dry lamination / hot lamination / solventless lamination / Rotogravure coating machines /gluing / bonding / tandem lamination Model CH-800S / CH-1000S / CH-1200S / CH-1500S / CH-2000S / CH-3000S / CH-5000S CH-800T / CH-1000T / CH-1200T / CH-1500T / CH-2000T / CH-2KT CH-3000T / CH-5000T / CH-8000T CH-3KT / CH-5KT / CH-8KT / CH-10KT / CH-12KT / CH-15KT / CH-20KT CH-3KD / CH-5KD / CH-8KD / CH-10KD / CH-12KD / CH-15KD / CH-20KD Substrate material HDPE, LDPE, LLDPE, MLLDPE, PET, PVC, PP, OPP, CPP, BOPP, PI, PS, PC, EVA, Nylon, PTFE, PU, TPO, TPE, TPO, Bio degradable , Biodegradable, Bio-degradable, Stretch film PE woven, PP woven Hollow profile sheet, corrugated sheet, Cartonplast, Polyflute, Coroplast , FlutePlast, IntePro, Proplex, Correx, Twinplast, Corriflute, Corflute Metalized film, FPC, Foil, copper foil, electrodepositedcopperfoil, CCL Non woven, Melt blown, Fabric, textile

ZIPPER BAG BLOWN FILM MACHINE

Categories : Blown Film Extruders

Designed to produce single line & double lines zipper bags, double zipper bags are upto the bags size & die. Different range film length should match different die & cooling ring Color injection extruder is an option.

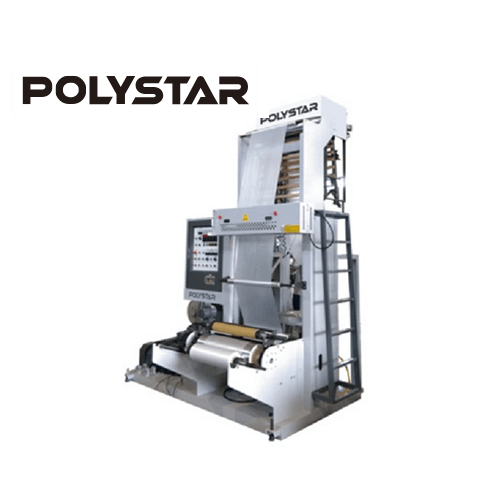

One Layer HDPE LDPE LLDPE 800mm Mini Type Blown Film Machine

Categories : Blown Film Extruders

Film width up to 800mm 40mm~55mm screw General Flexible Packaging

HDPE Blown Film Machine

Categories : Blown Film Extruders

HDPE Blown Film Machine In the past 30 years, we have been keeping receiving very good reputation from our worldwide customers on our quality products and satisfactory services.

Blown Film Take-Up Unit

Categories : Blown Film Extruder Parts

HSIN LONG Setting in the highest part of Plastic Film Blowing Machine, the most classic type of Take-Up Unit is suit for most Blown Film Machines. Different with the Oscillating Haul-Off, the volume is smaller and not take spaces.

PP Blown Film Machine

Categories : Blown Film Extruders

Water cooling system makes glossier and more transparent PP film for food or garment packing. Unique screw provides high production for a long period life and holds film uniformly steady. Dry chamber provides a fast water removal, for food package purpose. Optional tension control for winder provides good tension film in rolls, used in food packaging & printing. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.