Hydro Dipping Machine - Semi-Automatic - YHT223AXF

Categories : Hydro Dipping Spraying Equipment

Dipping Tank + Auto Film Layer + Auto Spray System Dipping Tank 3 meters length. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. YHT-223A2XF This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. This system can memorize multiple sets of different processes. YHT-223A2XF is perfect for large product and medium quantities of production/day

2-in-1 Conveying Dryer (CD)

Categories : Dryers and Dehumidifiers For Plastic Materials

Hopper dryer combine vacuum loader is perfect to move anywhere for your need. A stainless insulated hopper dryer with dual layer to help drying better and faster. Save more energy and increase higher efficiency. A vacuum loader automatically supplies dried resin to avoid the shortage of material during production. Installed pipe-clean device (Taiwan Pat:M299801) and closed-loop can prevent the moisture return, static electricity and resin pollution inside the pipe for better quality. Patented Heat-recycler (Taiwan Pat:226245;China Pat:01258213.1) can save your energy, increase drying and decrease the pollution of hot air and dust. Installed weekly timer and safety protectors can save your labor cost and protect operators in better working environment. Only one control unit is convenient for you to monitor all suction points. Able to extend suction points up to four as 1 to 4 small central conveying system to supply resin for raw material areas and numerous molding machines. Save your equipment cost and space without extra spend.

Twin Shaft Shredder (Kroko Twin Series)

Categories : Plastic Shredders

Intelligent control system The program system monitoring the shredding status and allows automatically reverse and forward motion to keep most stability while creating best production. High radial loads with high efficiency and great stability The professionally designed shaft and blades are made with high wear-resistant steel and processed by heat-treatment to increase the service life. It can withstand higher radial load and create higher efficiency while keep the best stability.

Twin Shaft Shredder

Categories : Plastic Shredders

Design especially for bulky plastic products. Eliminate the disadvantage of traditional high horse power crusher. Also for cracking unusual objects, waste tyres, logs, sleepers, etc. High capacity; low noise; installing easy replaced screen makes the desired output size available The knife is detachable, mutiple used and can minimise the wear and tear cost Easy operation Particle in uniform size Customized size is accepatable

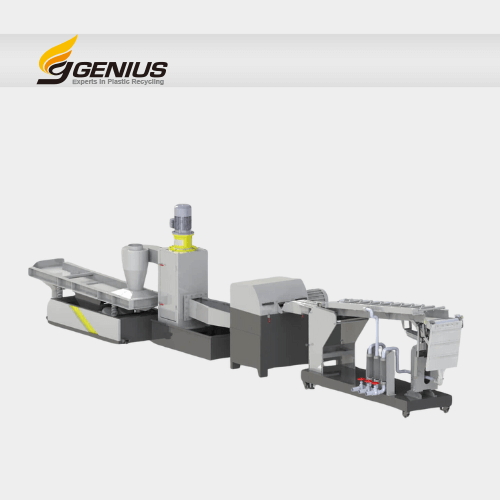

Automatic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Born For Extreme Automation The molten polymer been extruder from the die, fall into automatic water flow. High-pressure water flow from a special designed spray nozzle pulls the strands immediately while cooling at the same time. No more drawing strands before pelletizing. Minimize the lump waste during drawing the strands. GENIUS

Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Minimize The Powder Waste Suitable for higher MI or sticky materials. Production line is equipped with high-precision pellets cutter and specially designed vibrating screener.

Solvent-less Laminating Machine (WSL Series)

Categories : Industrial Lamination

For the solvent-free lamination, WORLDLY launches solvent-less laminating machine WSL series. The manipulation is much easier and simple with the PLC digital control system and touchable human-machine interface. Solvent-less laminating machine WSL series is the leading popular machines for solvent-free. It has higher compound speed in order to increase productivity. And, there is no wasted costs caused by the solvent evaporation. Also, the coating thickness is very thin with 100% solid ingredient which can reduce a lot of cost. The production won't produce solvent evaporation and there is no solvent residue. It all conforms to food safety regulations. Meanwhile, there's no need for drying chamber which can save energy. The machine itself can be shorten to save space for additional use which can make a significantly cost reduction.

Single Shaft Shredder (Kroko Series)

Categories : Plastic Shredders

Cost Effective Precision Installed with STM gearbox made from Italy. Ensure the best effective precision and the higher torque density. High radial loads with high efficiency and great stability Equipped with professionally designed shaft and blades, it can withstand higher radial load and create higher efficiency while keep the best stability. GENIUS

Sleeve Rewinding and Inspection Machine - Reversible Series-FSP 250-2

Categories : Slitters and Rewinders

The FSP-250-2 is an ideal re-reeling machine for round roll material inspecting process such as printing, surface or the seaming quality of shrink sleeves. 2 motors driven system and memorized reverse function allowed the winding direction changed during operation.

Sleeve Rewinding and Inspection Machine (Reversible) - FSP-250-2

Categories : Slitters and Rewinders

The FSP-250-2 is an ideal re-reeling machine for round roll material inspecting process such as printing, surface or the seaming quality of shrink sleeves. 2 motors driven system and memorized reverse function allowed the winding direction changed during operation.

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Side feeding barrel is better for storage and steady material input at same time. Main Extruder can extrude the material whose moisture below 7%. Sub extruder conducts second time filtering and ventilating for dirtier materials. Die face cutting frame made in SUS304 to prevent the rust and corrosion. Knives adjustments automaticlly patent design.The knife and die plate always set at 90 degree. No need to adjust frequently. High speed dryer is soundproof with double layer sealing design. The underneath water tank can gather the waste water and filter the impurity. Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryer. The triple layers vibrating screener is easy to clean, disassemble and assemble. Can customize the diameter of the hole. Blower with noiseless design. Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

Force Hopper Feeding Plastic Recycling Machine (H Series)

Categories : Plastic Pelletizer Machines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost save up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

“Standard” Series SG-23E/30E/36E

Categories : Granulators

SG-23/30E series granulators have no significant differences with the standard model in construction and operability. The granulators feature quick blade change. They are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding and extrusion machines. Staggered blades can easily grab and granulate the materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.

Plastic Recycling Machinery and Equipment

The equipment is specially designed for reproducing wastage from PP/HDPE woven bags. BOPP, film.

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Hot Die Face Pelletizing System

Categories : Plastic Pelletizer Machines

Cost Reduction The molten polymer from the extruder is passed to the die head. A rotating blade cuts the hot material as it exits the die hole and falls into a water ring for cooling. The operator does not need to draw the strands, which reduces the lump waste during re-drawing. More Uniformity, More Profit The pelletizing cutter is a universal joint design. The cutter adjusts the blade automatically during operation. Final plastic pellets are in uniform size in order to be sold at a higher price and bring you more profit.

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean

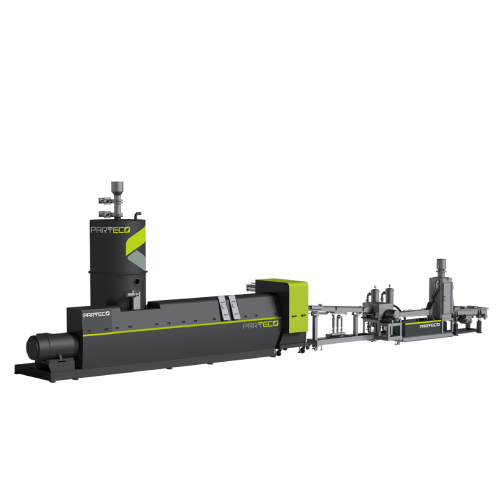

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pelletizer Machines

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly applied to the processing of PET crushed chips recycled from PET bottles. By means of vacuum degassing system to remove the water and impurities, then go through the melting extrusion, filtering and granulating process to tailor made the complete PET recycling solutions for you. Applicable materials Film or Flakes : PET Bottle Flakes

DHL Bag Making Machine

Categories : Sealing Machines

1. Servo Motor Driven, Efficient mechanical structure produce 180 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Universal Welding Device, easy operating and able to produce up to 15 kind of bag. 8. SHSS-T Twin Servo Motor Driven Model can produce two different size of printed plastic bag at same time. • The Conventional mechanical clutch / brake and rack & pinion system is also available.

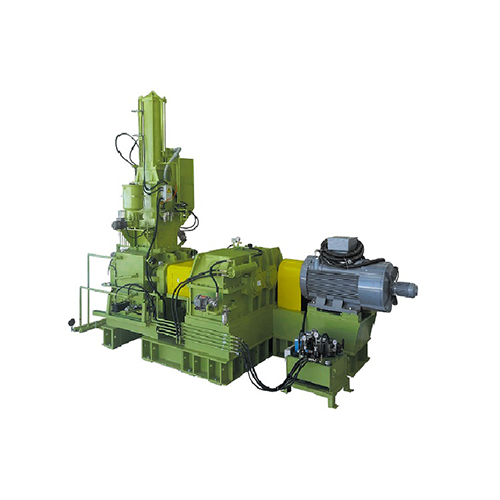

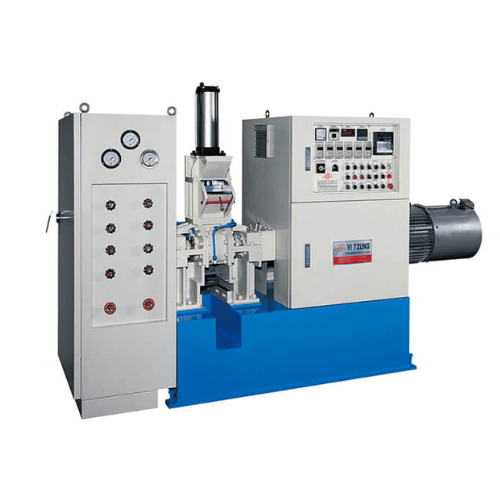

Intensive Mixer

Categories : Rubber Mixers

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber: Drill hole type jacket. Excellent cooling ability. Material contact surface: Hard chrome plating and fine polish. 3.Discharge door: Excellent sealing. No material leakage. 4.Ram: Drive by air cylinder. Good mixing and dispersion quality.

Screws And Barrels For Plastic Injection Molding

Categories : Screws and Barrels

Nan Yun's injection molding screw design team is able to provide ideal screw solutions for injection molding screw application. As the largest screw and barrel manufacture in Taiwan, Nan Yun has invaluable experience on screw barrel design for plastic moulding machine, vertical plastic injection moulding machine. there are more wear and tear on these components for injection moulding machine due to its cycle is longer than the rest of plastic machinery, so that it’s essential to have correct combination of material between screw and barrel for plastic injection molding to ensure a better performance and lasting lifetime.

Water Transfer Printing Dipping Machine- Semi-Automatic- YHT-222AX

Categories : Hydrographic / Water transfer Machines

YHT-222AX is 2 meters standard dipping machine with production arm which can dip various shapes of parts both manually or use production arm; and this machine also includes an auto spray system, working with both systems provide stable quality to the final product. The temperature controlled tank meet the medium volume requirement. High durability of tank structure with heavy loading production arm and water circulation by dual filters system are the best working tool for your Water Transfer Printing business. This transfer printing machine is perfect for large product and medium quantities of production/day.

Hydro Dipping Machine - Semi-Automatic - YHT222AXF

Categories : Hydrographic / Water transfer Machines

Dipping Tank + Auto Film Layer + Auto Spray System Dipping Tank 2 meters length. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

Hot Runner Temperature Controller - TC50

Categories : Control Equipment

HMI: 7”LCD display with touch panel Detecting the leakage of material Group setup function Mold Memory Power balance detection and display Synchronous heat up and cool down Self diagnosis log Arico

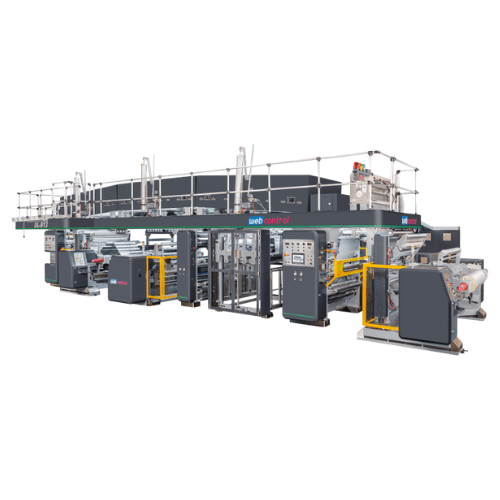

High Speed Mono Extrusion Coating & Laminating Machine (WEL-H Series)

Categories : Extrusion Coating Machines

In order to save the wastage of web path & minimized the film threading time. The machine adopt leading brands T-Die to ensure the stable performance & constant high quality coating gauge, The screw and barrel has strict designed & treated to achieve well mixed of resin. Whole machine automation and tension with PLC control and all un/rewinders with nonstop turret auto splicing.The operation of the machine is very simple and user-friendly. The high speed version of mono extrusion coating & lamination machine adopted more advance equipment, such as auto air gap adjustment unit and auto water temperature control device. Those extra function allow to saving many operation procedure during the production. Thus the operator can be more concentrated on major operation and enhance the finished product quality.This type of machine is suitable for more high productivity demand.

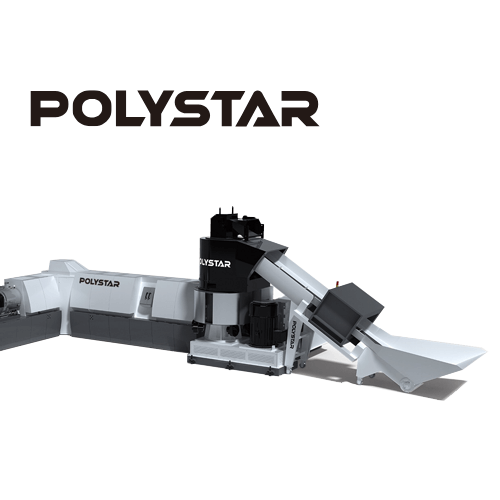

Two Stage Recycling Machine: Repro-FlexPlus

Categories : Plastic Waste Recycling Machines

Two Stage Recycling Machine with integrated cutter compactor. Improved degassing and filtration.

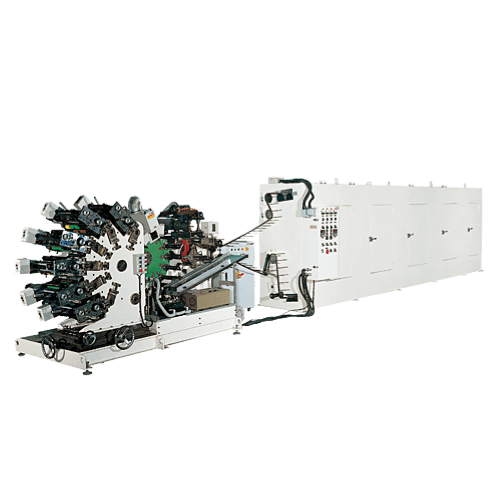

6 Color PE Tube Dry Offset Printing Coating Machine PCD-80-06-RE

Categories : Hot Stamping Machines

Precise index ensures accuracy of every movement. It is easy to disassemble the printing mandrel. Tube feeding system works with detector. Coating mechanism will not move. Without tubes on mandrels. Equipped with precipitator. Corona system can keep tube clean before printing. With optional sleeve printing mechanism. Tubes are headed directly after printing. No double-heading or double cutting procedures and save material. Vastly used on printing different shape of tubes.

Continuous Extrusion Blow Molding Machine with Visi-Strip function

Categories : Electric Blow Molding Machines

This series is excellent for producing containers such as engine oil bottles, machine oil bottles, gasoline bottles, and similar containers. A small screw can be specially installed to indicate the color of the bottle leveling line.

Laboratory Intensive Mixer

Categories : Dispersion Kneaders

The 1.8L Laboratory Intensive Mixer is designed for material research and develpment applications in the laboratory. The heating chamber (mixing chamber) and rotorsave built with water circulation sleeves assuring excellent cooling affect and heat transfer efficiency.

Force Side Feeding Plastic Recycling Machine (RECO Series)

Categories : Plastic Pelletizer Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. More Labor-saving The feeding control system monitors the ampere and controls the feeding speed automatically. Only 1~2 operators are required for an entire plant. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Force Side Feeding Plastic Recycling Machine (RECOi Series)

Categories : Plastic Waste Recycling Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Cutter Compactor Plastic Recycling Machine (KRIEGER Series)

Categories : Plastic Crushers

Compacting & feeding The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

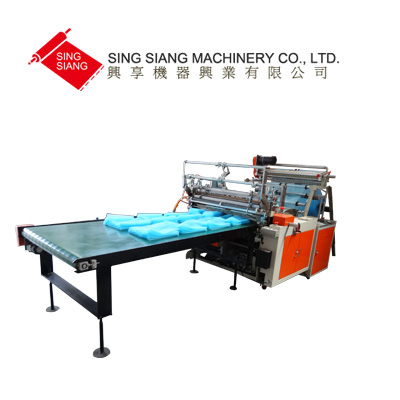

Bag Making Machine for Flower Sleeves

Categories : Bag Making Machine by Applications

Servo motor - Accuracy and highspeed @180 bags Malfunction alarm / stop - Abnormal temperature / No material feed / Photocell track miss / Bag jam

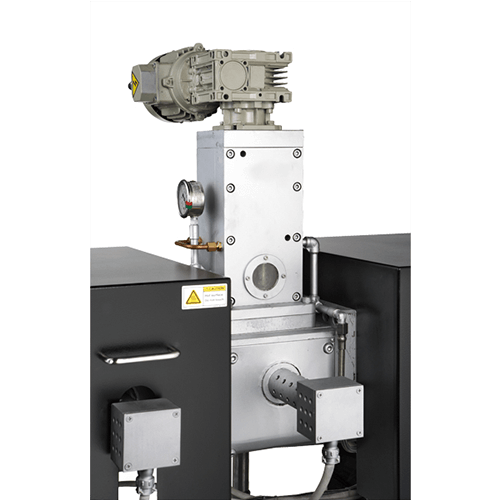

Anti-Leakage Vacuum

The PSY Anti-overflow vacuum seat from Sino-Alloy is designed for plastic or rubber, food or pharmaceutical processes. It’s an important accessory to the PSM extruder.

Twin Servo Motor Driven Flying Knife Bottom Sealing Bag Making Machine

Categories : Plastic Bag Making Machines

● Model:SHCG-75 ● Output Cycle/min:Max 5-30 ● Max Width:1600mm ● Max Length:3000mm 1. Twin servo motor driven, efficient mechanical structure. 2. Digital control for production length adjusting, precise and less wastage. 3. High production efficiency to save manpower and time. 4. Automatically stop when the temperature not reaching setting. 5. Automatically stop when running out of film or bag jams. 6. Flying knife device by servo motor control, unnecessary to adjust the cutting blade. 7. Using up and down heater for front sealing device, especially for heavy duty thickness up to 0.6mm. 8. With pneumatic unwind unit to lift up the film roll automatically.

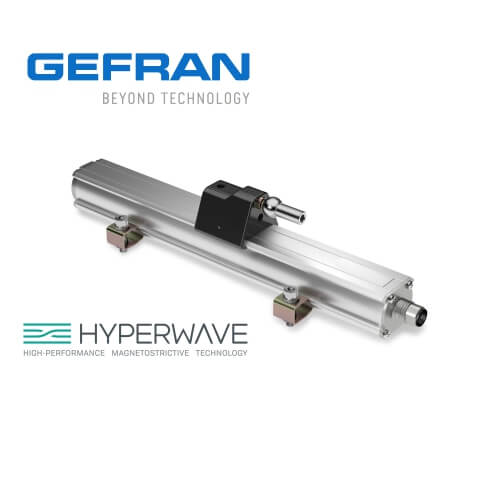

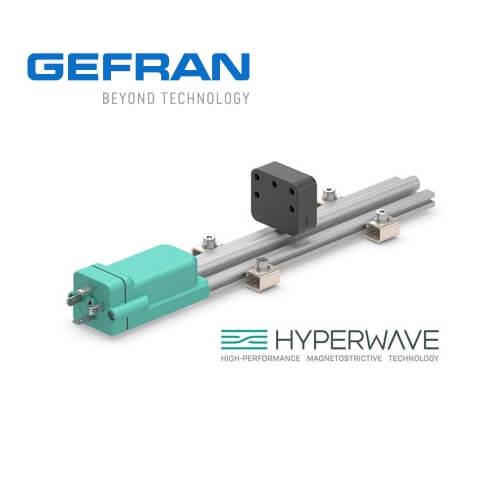

WPP-A Contactless Magnetostrictive Linear Position Transducer(Analog Output)

Categories : Indicators and Sensors

Contactless linear position transducer with HYPERWAVE magnetostrictive technology. The absence of electrical contact on the cursor eliminates all wear and guarantees almost unlimited life. High performance in terms of environmental IP protection and EMC immunity. High accuracy of the mesurement with reference to the non linearity, repeatability and hysteresis. High resistance to vibrations, mechanical shocks for use in a harsh industrial environment.

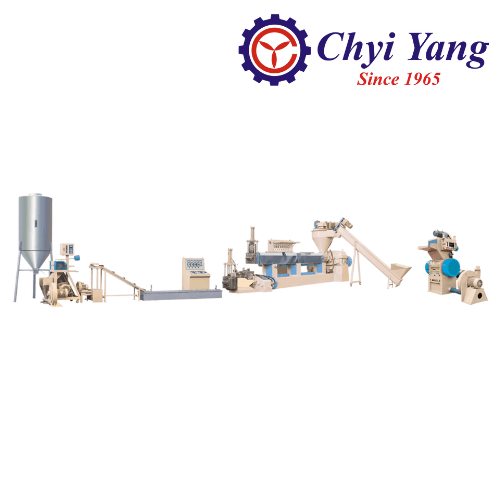

WASTE PLASTIC RECLAMATION & PELLET REGENERATING MACHINE (SPAGHETTI TYPE)

Categories : Plastic Pelletizer Machines

Available for dry and wet material, but you need to advise us in advance Simple operation & high capacity Application for PP, HDPE, LDPE, LLDPE, PS etc. Double extruder is used for better degasification Forced feeding for film We didn’t show all our models, please don’t hesitate to contact us for other size of recycling machines.

Gas Assisted Injection Molding System

Categories : Automatic Injection Molding Machine

-With touch panel & graphic display for monitoring pressure within the mold. -5 Stages of air pressure of and flow control. -Closed-loop pressure control from 25~300 kg/cm2; response time is less than 1.5 seconds. -Effectively prevent product from sinking and shrinking. -Material saving, keep the cost down.

Dry Laminating Machine Shafted Type DL-1000/1300

Categories : Industrial Lamination

This machine is for the Laminating process that uses a solvent-based adhesive. Reliable tension control with a mature lamination process able to make high-end products such as retort, sterilize and medical pouches. The gravure coating station allows high precision and consistency in coating weight. An efficient drying tunnel has high performance in vaporizing solvent completely to keep the product safe. Various options of heating solutions for drying tunnels are available. The energy-saving system is an option to help decrease carbon footprint and the cost of production

40TB Temperature And Pressure Double Indicator / Alarm Unit

Categories : Indicators and Sensors

Inputs configurable from faceplate. Easy strain-gauge calibration with sensitivity auto-ranging. Control of sensor power supply (input 1). Selectable code protection. Possibility to configure the unit. Power supply for transmitters. Easy to configure . Custom linearization available. Engineering units of the most common physical quantities available either on display or on labels. Acquisition and alarm programmable from 15 up to 120 msec. with resolution from 16000 to 4000 divisions Retransmission of variable values 3 alarms completely configurable from faceplate. 4-wire, configurable serial line. Protocol: GEFRAN CENCAL or MODBUS

Seaming Machines SEAM-350D-COMPACT (K4)

Categories : Shrink Sleeve Machinery

-for Shrink sleeve. -Increase production. -Non stop Turret. Features -Increase production. -Decrease inspection time. -Reduce waste. -Decrease labor.

M3 Series Melt Pressure Transducers-MV / V Output

Categories : Indicators and Sensors

The M3 series of Gefran, are pressure transducers for using in High temperature environment. The main characteristic of this series is the capability to read temperature of the media up to 400°C. The constructive principle is based on the hydraulic transmission of the pressure. The fluid-filled system assures the temperature stability. The physical measure is transformed in a electrical mea-sure by means the strain-gauge technology.

High Degree Water-type Mold Temperature Controller

Categories : Control Equipment

Economic and advanced design for high degree is your new choice. Water-type mold temperature controller (High Degree) do not pollute environment with oil gas that is the best choice for electronics, medical and cosmetic packing industries where strictly require better working environment. When oil-type model cannot satisfy for your need, you should change to water compression one. By direct supply method, it will not transform to steam even the temperature up to 160℃. Heat up faster, long machine life, high stability, precise control within ±0.3℃, and energy save for you. Precise temperature control and high stability control by 0.1℃ as a unit to display. The inaccuracy rate below ±0.3℃. Perfect for any precise requirement such as electronics industry. Heat-insulated design extend operating lifetime. PID temperature controller. Excellent overheat security protecting device. SSR relay control for durability. Unique design to prevent water leakage and pollution when mold is changed.

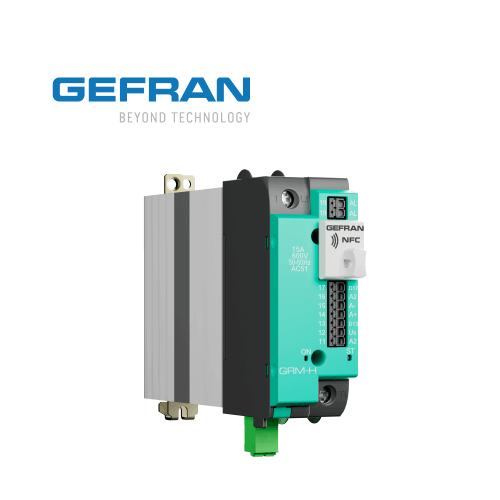

GRM-H Compact single phase Power Controller up to 120A

Categories : Control Equipment

The features of GRM-H Series Power Controllers ensure efficient heating management even in the case of complex electrical loads, which require special features, as in the case of infrared lamps or Silicon Carbide heating elements. Compact size from 15A to 120A Load voltage 480V, 600Vac Digital IO-Link communication Configurable control mode Zero Crossing, Burst Firing, Half Single Cycle or Phase Angle Feedback V,I,V2, I2, P, Z Soft start and current limits Logic command Vdc, Analog, PWM or IO-Link Advanced partial load break diagnostics (1/8) Slave control output (Two-phase/Three-phase) Configuration and Diagnostics via smartphone App with NFC technology Calibration and alarm reset commands via Digital Input Overview The ability to propose customized control solutions allows to rapidly satisfy the most different automation needs. For this purpose, the GRP series provides a wide range of extremely compact SSRs, with a solid basic structure but scalable as current sizes (from 15A to 120A), control type and configuration features. Control An accurate process control is the condition to achieve a constant and a high-quality production. To reach this goal it is necessary to manage in the best way the different types of industrial heaters from linear resistances to infrared lamps. For this purpose, the new series of SSR provides a series of control functionalities (ZC/ /BF/HSC/PA/Softstart) fully configurable to adapt to the various needs. Diagnostics Preventing possible anomalies allows to limit or eliminate harmful downtime and production. The GRP series includes dedicated functions such as the HB alarm for partial load breakage with accuracy of 1/8 of the total load, SCR short circuit, overtemperature and power failure. IO-Link communication Factory digitization is reaching its final frontier, the field level of the automation pyramid. In this level IO-Link is confirming itself as the most suitable communication to easily reach devices such as sensors and actuators. From this perspective, the GRP series has been developed to be integrated within this automation architecture. NFC configuration Simple and safe commissioning, maintenance and quick diagnostics are now within the capabilities of devices like SSR. All this thanks to the NFC technology, which allows to extend the user interface using normal Smartphone or Tablet as intelligent configurators. Thanks to an intuitive graphical user interface, setup or diagnostics are particularly easy.

MEMS Gas Mass Flow Meter 0-1000L/min

Categories : Separators

KMF1000 series digital gas mass flow meter is made of micro- electromechanical system (MEMS) flow sensing chip, suitable for a variety of purposes of clean, relatively dry nature of the small flow gas measurement and process control, unique packaging technology makes the product to meet the different ranges of flow measurement, to ensure high sensitivity, high reliability, high stability and low cost. It is based on a MEMS flow sensing unit and a high precision digital processing and calibration circuit (MCU). The integrated Δ-Σ A/D converter and the logic circuit with internal calibration function and MCU processor together ensure the real-time effective acquisition of the sensing signal, to obtain the accurate flow signal, and the corresponding compensation algorithm processing in the internal, so there is no need to do any external calibration and compensation to ensure high-precision.

WPG-A Contactless Magnetostrictive Linear Position Transducer(Analog Output)

Categories : Indicators and Sensors

Strokes from 50 to 1500 mm Sliding or floating magnetic cursor Direct and reverse analog output for displacement Standard valve or M12 connector Work temperature: -20...+75°C IP67 protection Power supply 24Vdc ±20% Electromagnetic compatibility EMC 2014/30/EU Compliant to the directive RoHS 2011/65/EU

Servo Motor Driven Filter Bag Making Machine

Categories : Bag Making Machine by Applications

1. Servo Motor Driven, Efficient mechanical structure produce 120 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Equip with Front Thick Bags Sealing Device, will able to produce any long length of bags. 8. SHCG-T Twin Servo Motor Driven Model can produce two different size of printed plastic bag at same time. • The Conventional mechanical clutch / brake and rack & pinion system is also available.