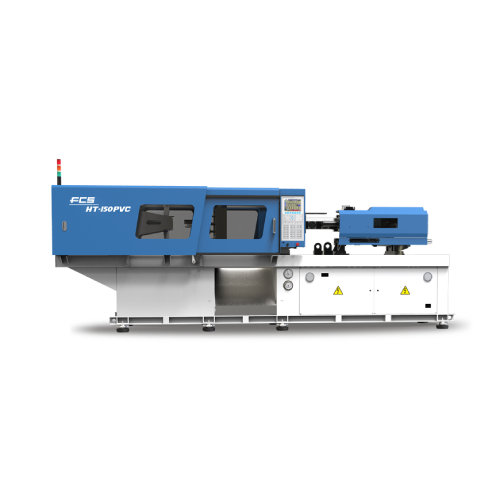

PVC Pipe Fitting Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The PVC injection molding machine is for producing PVC pipe fittings used in building and construction industries, such as pvc socket, pvc tee, pvc elbow, pvc coupler, and pvc valve.

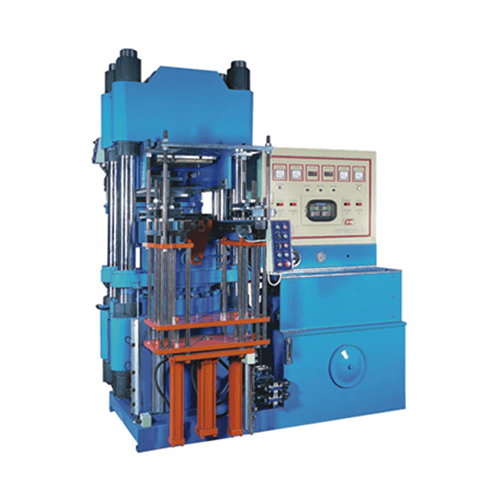

3RT Mold-Open Rubber/Silicon Continuous Transfer Injection Molding Machine-TCC-S3

Categories : Compression Molding Machines

●Nature rubber ●Rubber of metal boned parts ●Oil resistance rubber ●NBR+PVC concoction ●Synthetic rubber ●Medical/Pharmaceutical usage rubber ●Heat resistance rubber

Rubber Back-Injection Molding Machine

Categories : Rubber Injection Molding Machines

Rubber Back-Injection Molding Machine Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

PVC Injection Molding Machine 90PVC to 320PVC

Categories : Horizontal Injection Molding Machines

Common commissioning for molding products such as fittings of a highly acid chemical. A one-piece rod and a standard L/D ratio screw design makes melt flow smoothly. Includes a standard, grade B, bimetallic screw barrel to provide a better wear-resistance and lifespan. Radiation fans set on top of the sleeve of the barrel to avoid overheating issues of the rigid PVC inside of the barrel.

Wire / Plug Machine Y-V SERIES

Categories : Vertical Injection Molding Machines

- Vertical clamping / vertical injection, suitable for general electrical plugs, electronic components and other small insert molding. - Two or three stage temperature control / injection speed / non-stage adjustment of back pressure, etc., more suitable for parts molding of precision plastic. - Quick mold locking / low pressure low speed to mold lock, a special safety design to protect the mold. - Lower mold fixing/upper mold movable; with fine positioning for molding piece in mold. The device is equipped with hydraulic ejector for easy removal of the product. - Electric-control fittings / hydraulic fittings using domestic brands in precision, durability and low noise. The Clamping force is 15-25TON with PLC programming electric-control computer in single- comparison- pressure control or computer in full ratio (compare voltage; compare current); there are three options available to customers. - A single sliding mold 1S and two sliding mold 2S can be added, enabling the operation to be more efficient and safer in production.