“Standard” Series SG-23E/30E/36E

Categories : Granulators

SG-23/30E series granulators have no significant differences with the standard model in construction and operability. The granulators feature quick blade change. They are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding and extrusion machines. Staggered blades can easily grab and granulate the materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.

Plastic Recycling Machinery and Equipment

The equipment is specially designed for reproducing wastage from PP/HDPE woven bags. BOPP, film.

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Hot Die Face Pelletizing System

Categories : Plastic Pelletizer Machines

Cost Reduction The molten polymer from the extruder is passed to the die head. A rotating blade cuts the hot material as it exits the die hole and falls into a water ring for cooling. The operator does not need to draw the strands, which reduces the lump waste during re-drawing. More Uniformity, More Profit The pelletizing cutter is a universal joint design. The cutter adjusts the blade automatically during operation. Final plastic pellets are in uniform size in order to be sold at a higher price and bring you more profit.

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean

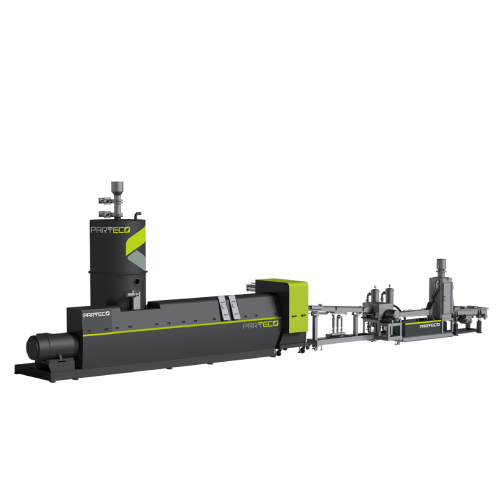

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pelletizer Machines

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly applied to the processing of PET crushed chips recycled from PET bottles. By means of vacuum degassing system to remove the water and impurities, then go through the melting extrusion, filtering and granulating process to tailor made the complete PET recycling solutions for you. Applicable materials Film or Flakes : PET Bottle Flakes

DHL Bag Making Machine

Categories : Sealing Machines

1. Servo Motor Driven, Efficient mechanical structure produce 180 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Universal Welding Device, easy operating and able to produce up to 15 kind of bag. 8. SHSS-T Twin Servo Motor Driven Model can produce two different size of printed plastic bag at same time. • The Conventional mechanical clutch / brake and rack & pinion system is also available.

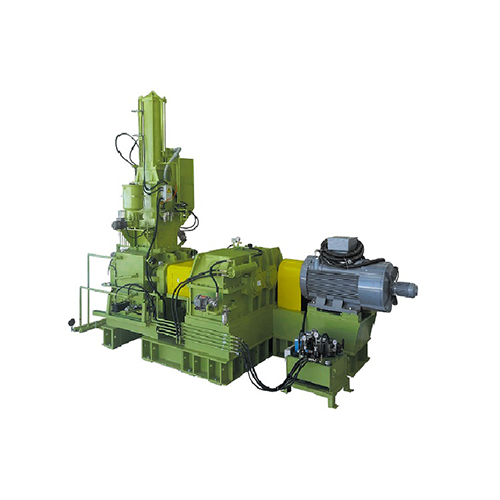

Intensive Mixer

Categories : Rubber Mixers

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber: Drill hole type jacket. Excellent cooling ability. Material contact surface: Hard chrome plating and fine polish. 3.Discharge door: Excellent sealing. No material leakage. 4.Ram: Drive by air cylinder. Good mixing and dispersion quality.

Screws And Barrels For Plastic Injection Molding

Categories : Screws and Barrels

Nan Yun's injection molding screw design team is able to provide ideal screw solutions for injection molding screw application. As the largest screw and barrel manufacture in Taiwan, Nan Yun has invaluable experience on screw barrel design for plastic moulding machine, vertical plastic injection moulding machine. there are more wear and tear on these components for injection moulding machine due to its cycle is longer than the rest of plastic machinery, so that it’s essential to have correct combination of material between screw and barrel for plastic injection molding to ensure a better performance and lasting lifetime.

Water Transfer Printing Dipping Machine- Semi-Automatic- YHT-222AX

Categories : Hydrographic / Water transfer Machines

YHT-222AX is 2 meters standard dipping machine with production arm which can dip various shapes of parts both manually or use production arm; and this machine also includes an auto spray system, working with both systems provide stable quality to the final product. The temperature controlled tank meet the medium volume requirement. High durability of tank structure with heavy loading production arm and water circulation by dual filters system are the best working tool for your Water Transfer Printing business. This transfer printing machine is perfect for large product and medium quantities of production/day.

Hydro Dipping Machine - Semi-Automatic - YHT222AXF

Categories : Hydrographic / Water transfer Machines

Dipping Tank + Auto Film Layer + Auto Spray System Dipping Tank 2 meters length. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

Hot Runner Temperature Controller - TC50

Categories : Control Equipment

HMI: 7”LCD display with touch panel Detecting the leakage of material Group setup function Mold Memory Power balance detection and display Synchronous heat up and cool down Self diagnosis log Arico