AUTOMATIC MELT FILTER- TEN

Categories : Plastic material waste recycling machine

TEN is FIMIC’s automatic screen changer capable of blocking even the smallest contamination particles thanks to its mesh, whose resistance allows to adapt the temperature according to the req...

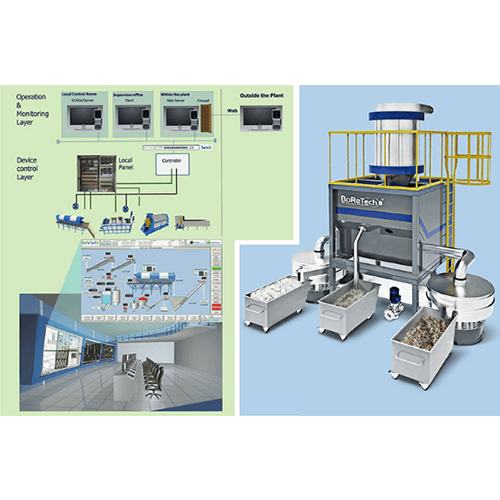

Instant Recycling System

Categories : Plastic material waste recycling machine

In the past, operators throw away the sprues or waste material in small amount or wait for collecting them in big amount to reuse. However, that may be stuck dust by static electricity become too b...

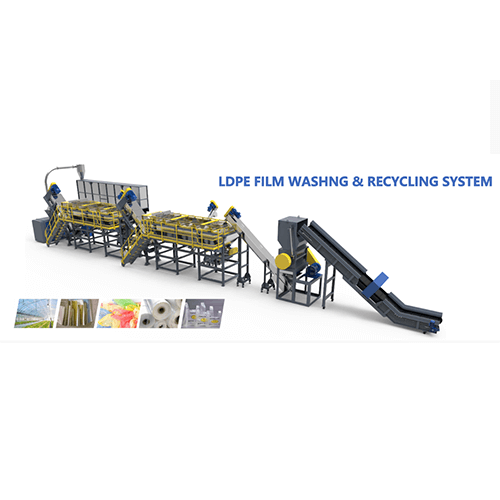

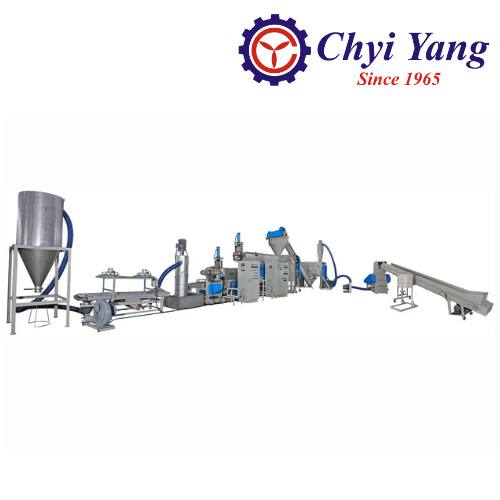

Film Washing Line

Categories : Plastic material waste recycling machine

Solution for different level of plastic films The film washing line equipped crushing, washing and drying units. Which allowing to process different dirty levels of materials, from agriculture film...

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

Categories : Plastic material waste recycling machine

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

PET Bottle Recycling System

Categories : Plastic material waste recycling machine

PET Bottle Recycling System

Success Story - Cutter Compactor Plastic Recycling Machine

Categories : Plastic material waste recycling machine

KRIEGER-85 / Cutter Compactor Plastic Recycling Machine / LDPE Film / USA KRIEGER-125 / Cutter Compactor Plastic Recycling Machine / LDPE and HDPE Film / Indonesia KRIEGER-100 / Cutter Compactor Pl...

FILM/BAGS WASTE PLASTIC RECYCLING MACHINE : KCR-150

Categories : Plastic material waste recycling machine

Each blown film machine is equipped with an electronic length counter and an accumulated time meter. In addition, all main output shafts are precision ground for exceptional stability and quiet ope...

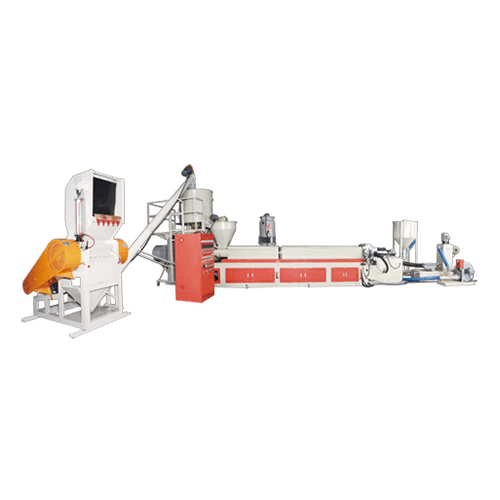

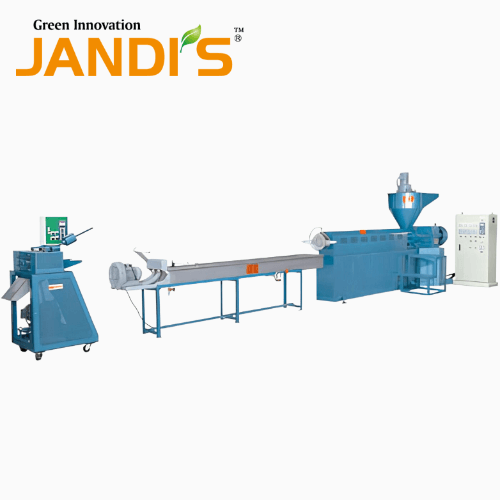

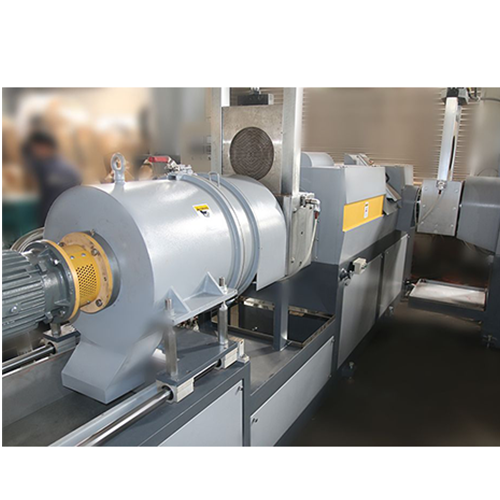

Force Feeding Single Stage Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic material waste recycling machine

High torsion, low-noice; temp. controls stability; double degassing, Suitable for a variety of raw materials, Easy to operate; prority transcends traditional model, Spaghetti cutting is suitab...

Automatic self-cleaning screen changer - RAS

Categories : Plastic material waste recycling machine

Any contamination the filter collects is scraped from its surface by two blades, and then gathered by the blade-holder. Finally, anything harvested is automatically ejected through the front valve....

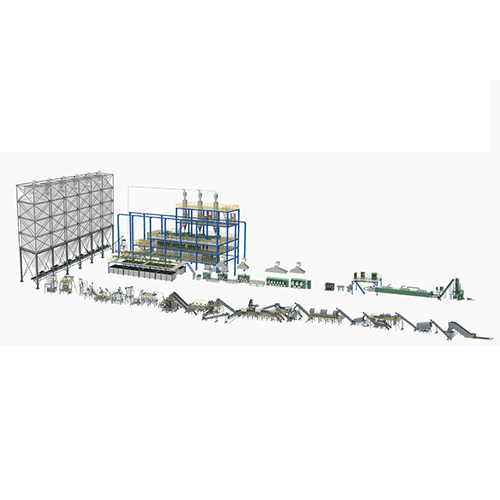

Waste PET Bottles to Polyester Staple Fiber Production Line

Categories : Plastic material waste recycling machine

Waste PET Bottles to Polyester Staple Fiber Production Line

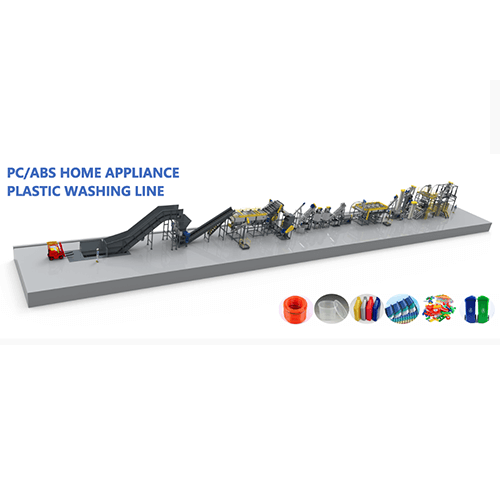

Rigid Plastics Recycling System

Categories : Plastic material waste recycling machine

Rigid Plastics Recycling System

ABS/PP/PE Waste Plastic Recycling Making Machine

Categories : Plastic material waste recycling machine

ABS/PP/PE Waste Plastic Recycling Making Machine

EXCLUSIVE MELT FILTER- GEM

Categories : Plastic material waste recycling machine

Differently from RAS, this model reaches a greater filtering surface due to the presence of two filtering meshes towards which all the melt is directed, alongside two scrapers and independent disch...

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

Categories : Plastic material waste recycling machine

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

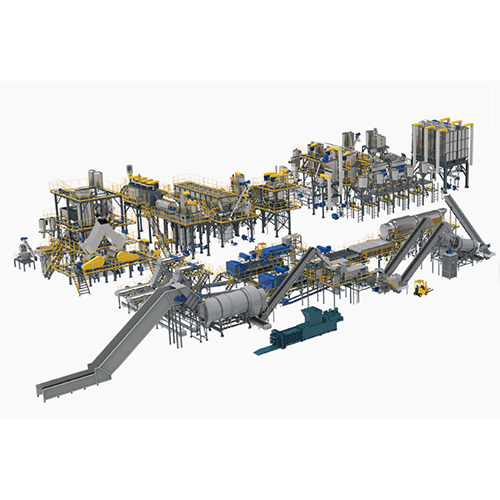

Rigid Plastics and PE Film Recycling System

Categories : Plastic material waste recycling machine

Rigid Plastics and PE Film Recycling System

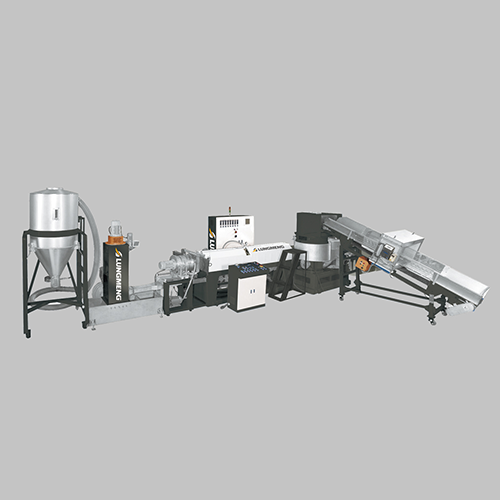

Pelletizing & Recycling System

Categories : Plastic material waste recycling machine

MGB-RPW-65 For PP, HDPE and LLDPE recycling.

Micro Denier Filament Grade PET Bottle Washing Line

Categories : Plastic material waste recycling machine

Micro Denier Filament Grade PET Bottle Washing Line

Success Story - Force Side Feeding Plastic Recycling Machine

Categories : Plastic material waste recycling machine

RECO-Z-125i / Force Side Feeding Plastic Recycling Machine / Washed PE Film / Taiwan RECO-Y-150i / Force Side Feeding Plastic Recycling Machine / HDPE bottle / Taiwan

WASTE PLASTIC RECYCLING & PELLETIZING MACHINE (DIE CUT TYPE)

Categories : Plastic material waste recycling machine

Pelletizing Machine Available for PE material Simple operation & high capacity Plastic Recycling machine Application for HDPE, LDPE, LLDPE The motor & screw length ratio ...

Single Screw Squeezing Drying Machine

Categories : Plastic material waste recycling machine

With a special designed screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granul...

Plastic Recycling Machine - WTS Series

Categories : Plastic material waste recycling machine

WTS85, WTS100, WTS120, WTS150 RECYCLING PE/PP/ABS/PS

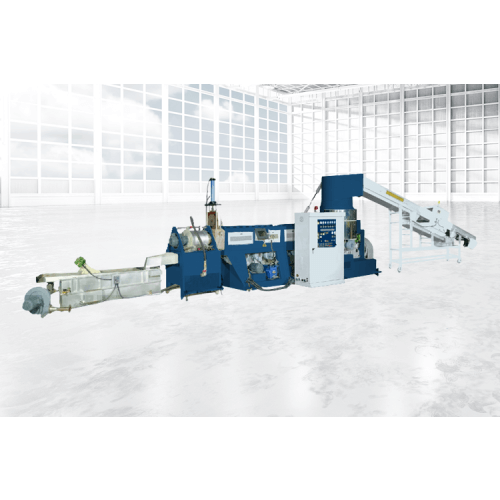

3-in-1 Plastic Recycling and Pelletizing Machine

Categories : Plastic material waste recycling machine

The machine consists conveyor, shredding drum, extruder and pelletizer to integrate the production to minimize working time and save the manpower.